Ürün arama

Açıklama

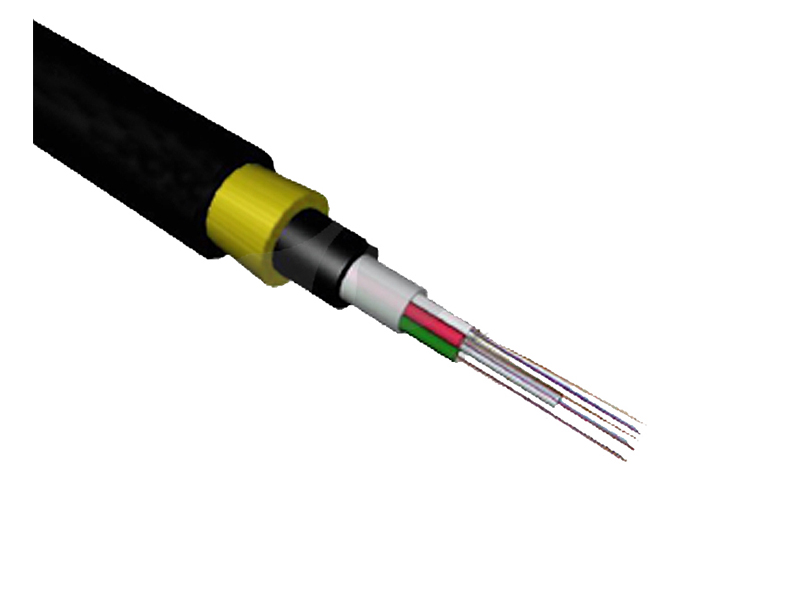

ORing 8 Core 50/125 Mm Om3 Tek Tüplü Çelik Zırhlı Fiber Optik Kablo

Özellikler

Ürün Kodu : FO108M3

Teknik Özellikler

| ÖZELLİKLER | BİRİM | DEĞERLER | TEST STANDARTLARI |

| TENSILE STRENGTH AT BREAK | kN | >1.2 | EN 60794.1.E1 |

| BREAKING TENSILE STRENGTH | kN | >1.5 | EN 60794.1.E1 |

| CRUSH RESISTANCE | N/cm | >200 | EN 60794.1.E3 |

| REPEADING BENDING RADIUS | mm | <20xD | EN 60794.1.E6 |

| SINGLE BENDING RADIUS | mm | <15xD | EN 60794.1.E6 |

| TORSION | +90° C,8 | possitive | EN 187 000 M 508 |

| IMPCAT | kN | >1 | EN 187000 M 504 |

| TEMPERATURE | EN 60794.1.E11 | ||

| OUTER SHEATH | |||

| DENSITY | g/cm³ | >20 | ASTM D 638 |

| TENSILE STRENGTH AT BREAK | N/mm² | >400 | ASTM D 638 |

| ELONGATION AT BREAK | % | 2.Eki | ASTM D 1693 |

| E.S.C.R. (%10 lgepal C-630) | >500 hours | 2.Eki | ASTM D 746 |

| BREAKING COLD | <-75°C | 2.5+0.5 | ASTM D 1603 |

| CARBON BLACK RATE | % | <0.950 | ASTM D 792 METOT A |

| OXIGEN INDUCTION TIME | 200°C | >25 | IEC 811.4.2 B |

| TUBE GEL | |||

| DENSITY (25°C) | g/cm³ | +0.05 | DIN 51 757 |

| DROP POINT (24 HOUR) | °C | aooropriate | IEC 811.5.1 B |

| DRIP POINT (24 HOUR) | °C | >70 | REA PE 39 |

| FLASH POINT | °C | >230 | ISO 2592 |

| OIL SEPERATION (150°C, 24 HOUR | % | FTM STD 791 C | |

| VOLATILITY | % | <2 | FTM STD 791 C |

| WATER ARMOUNT | % | <0.05 | DIN 51 777 |

| ACID VALUE (100°C) | % (mg KOH/g) | <0.01 | DIN 53 402 |

| ABRATION | posıtıve | IEC 811.5.1 | |

| PENETRATION (25°C / -30°C) | 1/10 mm | >150 | ISO 2137 |

| OXIGEN INDUCTION TIME (180°C) | minute | >20 | IEC 811.4.2 B |

| 100-500V (100°) | Ω x m | >10 | ASTM D 1169 |

| 100-500V (23°) | Ω x m | ASTM D 1169 | |

| LOSE TUBE | >10,11 | ||

| DENSITY | g/cm³ | 1.31+0.03 | ISO 1183 |

| WATER ABSORPTION (23°C) | % | <0.45 | DIN 53 495 |

| TENSILE STRENGTH AT BREAK | N/mm² | <30 | ISO 527 |

| ELONGATION AT BREAK | % | >50 | ISO 527 |

| E-MODULUS | N/mm² | >2200 | ISO 527 |

| SHORE | Shore D | >78 | DIN 53 505 |

| MELTING TEMPERATURE (DSC) | °C | >220 | ISO 3146 C |

| LIN. THERMAL EXT. COEFF. (-23<<+80°C) | °K-1 x10-4 | <1.3 | |

| E-GLASS YARN | |||

| DENSITY | g/cm³ | offered | offered |

| TENSILE STRENGTH AT BREAK | % | offered | offered |

| ELONGATION AT BREAK | N/mm² | offered | offered |

| E-MODULUS | % | offered | offered |

| ARMOURING | |||

| STEEL THICKNESS | nm | 0.155±0.015 | ASTM A 623 M |

| TENSILE STRENGTH AT BREAK | N/mm² | >300 | ASTM E 6892 |

| ELONGATION AT BREAK | % | >15 | ASTM E 6892 |

| THICKNESS OF COATING | nm | >0.050±0.01 | ASTM A 623 M |

| DC RESISTANCE | ohm/km | <40 | ASTM A 6892 |